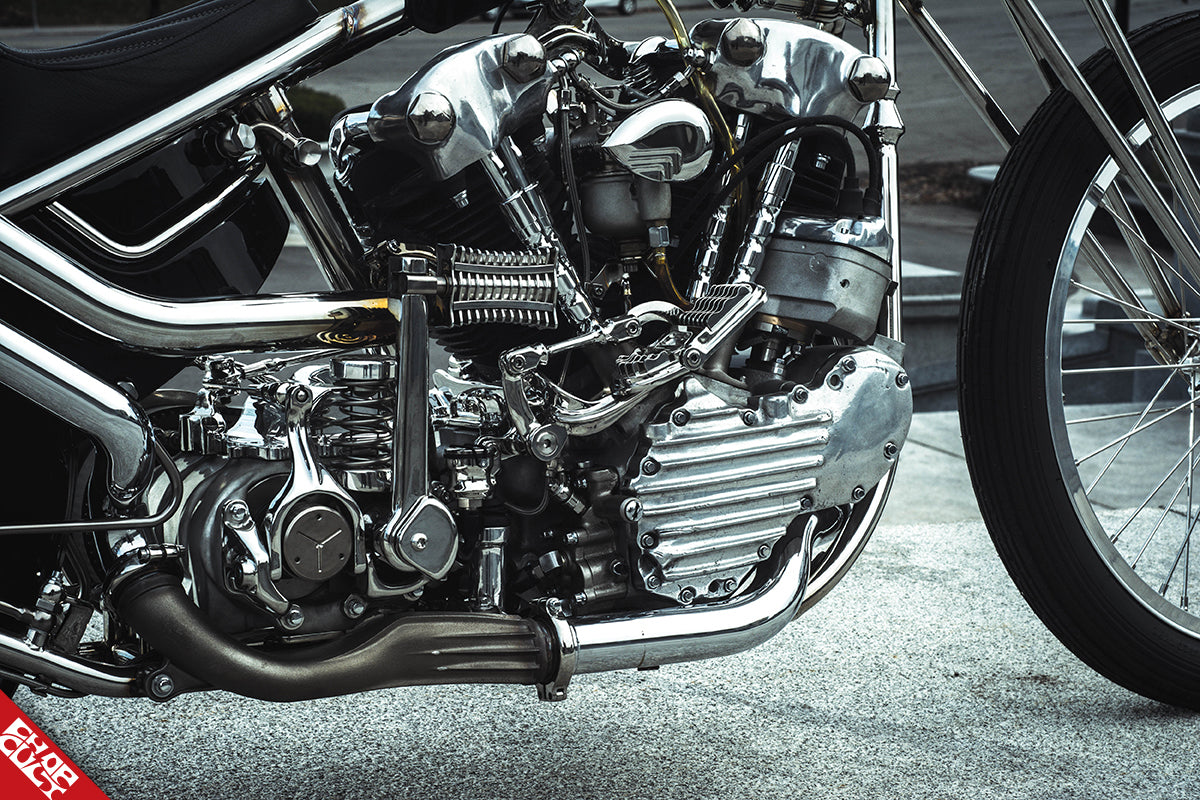

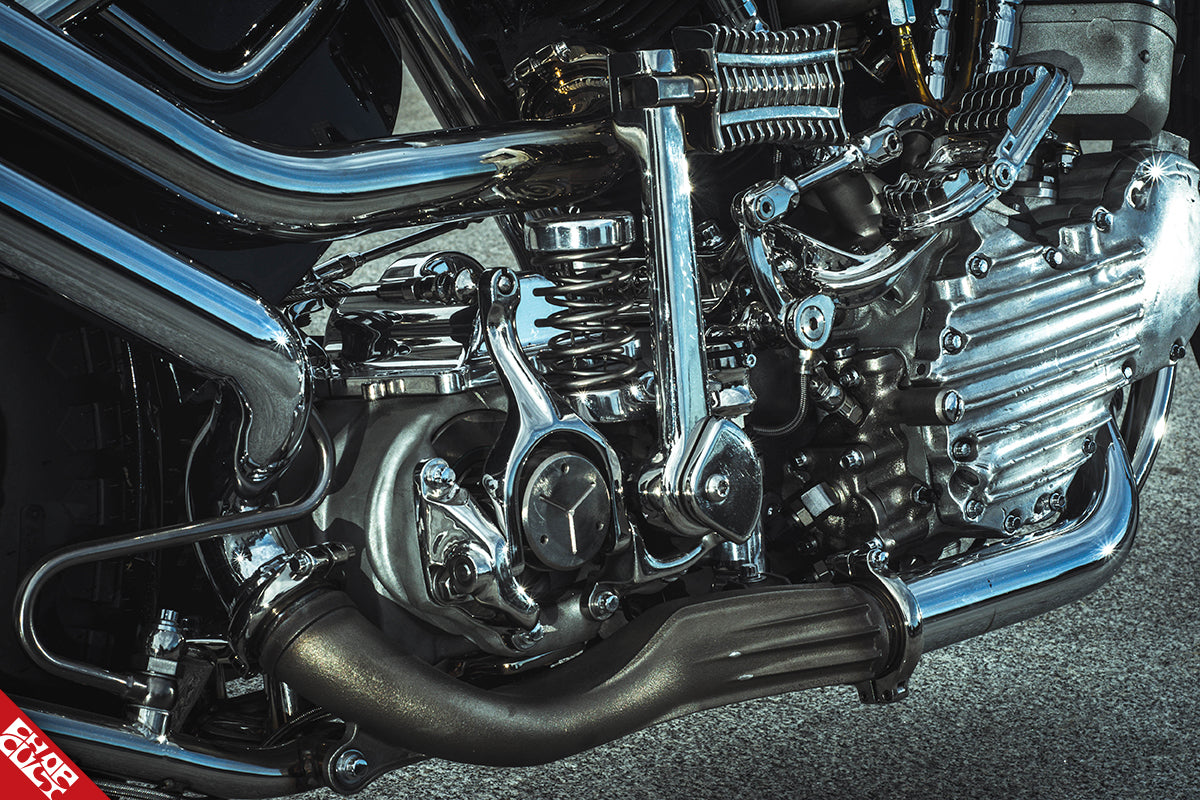

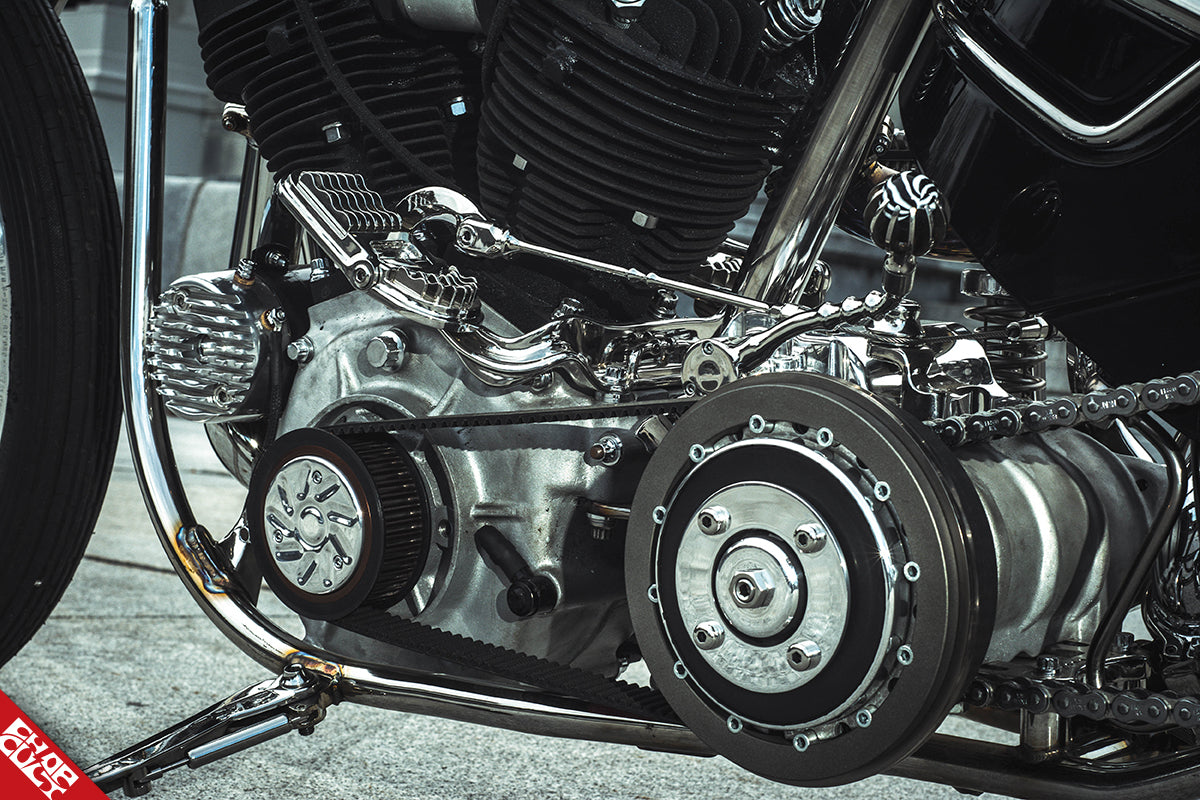

CT Newman's Show Stopping Stainless Knucklehead

I met Christian Newman just as he was finishing a pretty wild Nissan Skyline-powered BMW 325is; shortly after this he transitioned from cars to motorcycles, and I knew that he was going to blow some minds. One of his first serious builds was for the first Greasy Dozen in 2012; he built a turbo Shovelhead, with tons of custom parts, most all fabricated by him.

Not too long after completing the shovel, I remember Christian saying he had started building a girder front end for his next project which would be powered by a knucklehead. I saw some photos and posts of him bending and polishing stainless, machining parts, and getting some of the stainless castings back, and could tell this wasn't going to be a typical girder. I had stopped by a few times, and after seeing it polished and complete as a dining room table decoration, I knew this bike would be talked about for years before he even started. Christian isn't only a very talented engineer, but he taught himself how to be an incredible machinist as well. He spent his lunch breaks, evenings, and weekends building this bike for a solid year. I think the pictures will tell the rest of the story and illustrate his extreme attention to detail and fabrication skills.

I even got to sit down and ask Christian about some of his work:

Did you have any influences on the style or ideas while building your bike? I think my style evolved as time went by because of what I was able to create was constantly growing. The complexity of the parts increased as the build went along. I tried to ensure that each piece could stand on its own while still being part of a whole.

What was your favorite part of the bike to build? Probably the headlight support bracket. It’s just this dinky little arm, but it’s made from a few layers with a groove cut in it for the wire to run through. Most people don’t notice or think the headlight just isn’t hooked up.

Least favorite or hardest part to fabricate: The headlight. I built it from many layers of stainless and the amount of time I spent welding and grinding was rough, but the final product was worth it. It took about 50 hours to make.

Owner/builder: Christian Newman

Make Model: 1940 HD Knucklehead

Frame/chassis: Stainless steel custom

Front end: Stainless steel custom

Wheels: Custom asymmetric hubs w/ Buchanan spokes

Paint: Andy Zeon

Seat: Ginger McCabe: New Church Moto

Exhaust: Stainless custom

Transmission: Custom 4 speed, from scratch kicker section.

Be sure to follow Christian on Facebook and Instagram.

Thanks,

Note: This article was originally published 5/18/2022

Support ChopCult - Buy Merch

ChopCult Vest- Black

ChopCultThis Heavy Duty canvas riding vest is perfect to run as is or patch up as you see fit. ChopCult hacksaw logo embroidered on the front left chest an...

View full detailsSnap Back Hat ChopCult '66 Logo - Black

ChopCultSnap Back Hat ChopCult '66 Logo- Black ChopCult's '66 Logo embroidered on a black Yupoong Classics 5 panel snap back. Embroidered in the USA

ChopCult Big Twin Evolution Engine T-Shirt

ChopCultHarley Evolution Big Twin's are arguably the most bulletproof engine built by the MoCo! Rock your favorite drivetrain with this Graphic T Shirt. P...

View full detailsChopCult Knucklehead Engine T-Shirt

ChopCultRep your favorite motor with tasteful shirt featuring the iconic Harley Knucklehead Engine. Printed front left chest and full back on a 100% cotton...

View full detailsChopCult Hacksaw Hoodie

ChopCultPullover hoodie sweatshirt comes with the ChopCult logo on the front and the Hacksaw design on the back. Printed in the USA.